HÖRMANN Group exhibiting at 2018 IAA Commercial Vehicle Show

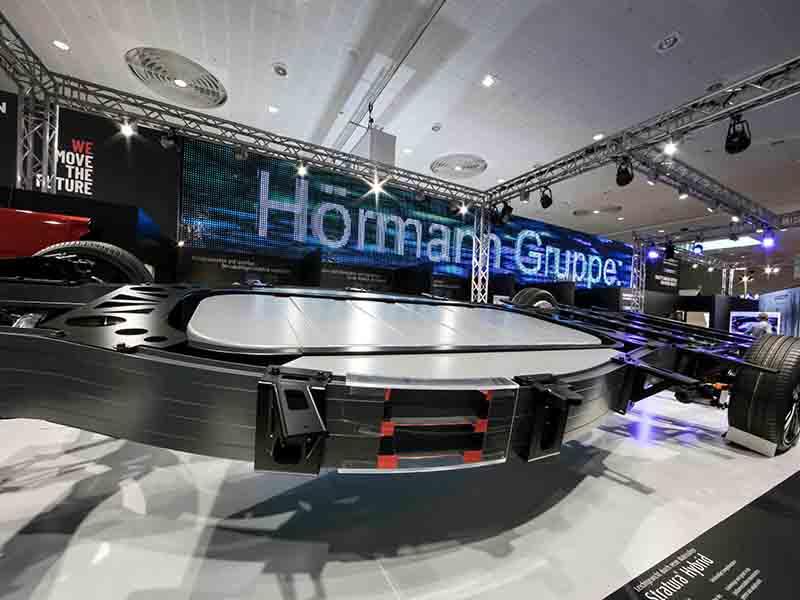

HÖRMANN Group is demonstrating the synergies created by its capabilities – particularly its Automotive and Engineering divisions – at the 2018 IAA Commercial Vehicle Show. The innovative integral chassis concept, which HÖRMANN Group is showcasing for the first time, is designed specifically to be used with alternative drive systems and pursues a lightweight structural approach that reflects the cost sensitivity of the transport industry in particular, as well as the vehicle design requirements of electric light commercial vehicles.

The overall topology of the chassis is reminiscent of structures found in nature that have oval shapes to protect their inner workings (such as clams, eggs, tortoises or nuts). The overall structure of the chassis itself protects the internal energy storage unit and is given additional support by load-adaptive structures on the longitudinal members. Using innovative forming technology, the company has taken inspiration from the natural world to make multi-chamber steel profiles that adapt to load, following the non-linear structure of the chassis and reproducible on wide-ranging systems without additional tooling costs thanks to smart manufacturing strategies. The HÖRMANN integral chassis combines the use of innovative, production-ready technologies with affordable materials with a smart lightweight modular structure on the basis of an overall structure and component structure optimised in line with a bionic model.

Enhanced protection for energy storage units

The performance of the system as a whole is enhanced by the purposeful use of highly effective composite lightweight materials. In addition to cost efficiency owing to scalable manufacturing technologies in line with topological optimisation and affordable materials, the chassis concept thus offers enhanced protection for energy storage units, which do not need as much additional protection when integrated in the overall system, thus saving weight.

In introducing the chassis concept, the company has added another string to its bow in terms of the lightweight commercial vehicle capabilities that it currently has to offer on the market through the production of large outer skin components. Development took place within the framework of a high-performance ecosystem, which HÖRMANN Automotive intends to use in future in its capacity as a system provider to assist customers in the fields of light and heavy-duty commercial vehicles as they make the transition to electric vehicles.